When Hardware Becomes Its Own Power Source

Imagine a world where your laptop’s frame is also its battery, where electric cars store energy in their body panels, and where drones fly longer because their wings hold the charge.

This vision is becoming reality thanks to Structural Battery Composites (SBCs) — a revolutionary technology combining energy storage and mechanical strength into a single multifunctional material.

First highlighted by the World Economic Forum, structural battery composites represent a new frontier in materials science. Instead of treating batteries and structure as separate components, SBCs merge them, potentially eliminating heavy battery packs altogether.

It’s not just an energy innovation — it’s a complete rethinking of hardware design, merging electrochemistry, nanotechnology, and engineering to create devices that are lighter, stronger, and more energy-efficient.

What Are Structural Battery Composites?

Structural Battery Composites (SBCs) are materials that can simultaneously:

-

Store electrical energy, like a conventional battery.

-

Provide structural strength, like carbon fiber or aluminum.

In essence, SBCs allow energy to be stored directly within the physical structure of a device. That means a laptop’s chassis, a car door, or even a drone wing could function as both the framework and the battery.

How They Work

An SBC typically combines:

-

Carbon fiber – acts as both the mechanical reinforcement and the negative electrode (anode).

-

Polymer-based electrolyte – conducts ions between the electrodes while serving as a load-bearing matrix.

-

Lithium-iron phosphate (LFP) or other cathode materials integrated into the composite.

This integration forms a solid-state structural battery, eliminating the need for separate battery cells and casing.

The Science Behind the Innovation

At its core, an SBC is a multifunctional composite material. Unlike conventional batteries, where energy and structure are isolated, SBCs use advanced material design to achieve dual performance.

Key Engineering Challenges Solved

-

Weight Reduction: By combining energy and structure, SBCs reduce total mass by up to 30–50%, critical for vehicles and aerospace applications.

-

Volume Efficiency: Eliminating bulky battery packs frees up space for design flexibility.

-

Integration: Batteries become part of the load path, not dead weight.

Materials Engineering

-

Carbon fibers provide high tensile strength and conductivity.

-

Solid polymer electrolytes replace liquid electrolytes, preventing leaks and improving safety.

-

Nano-engineered interfaces ensure seamless electron flow and mechanical bonding.

Recent prototypes from Chalmers University of Technology and KTH Royal Institute of Technology in Sweden demonstrated SBCs with energy densities around 24 Wh/kg and tensile stiffness of 25 GPa — enough to act as both a structural and electrical component.

While the energy capacity is currently lower than lithium-ion cells, researchers expect future versions to rival or surpass traditional batteries in performance.

Potential Applications Across Industries

The versatility of SBCs opens the door to innovation across multiple sectors.

1. Consumer Electronics: Laptops, Tablets, and Smartphones

One of the most immediate uses is in portable electronics. Imagine:

-

A laptop where the carbon-fiber body doubles as the battery.

-

A tablet that’s thinner and lighter because it no longer needs an internal battery pack.

-

Smartphones with flexible frames storing power within their own structure.

This could dramatically increase battery life, reduce heat output, and enable ultra-slim designs.

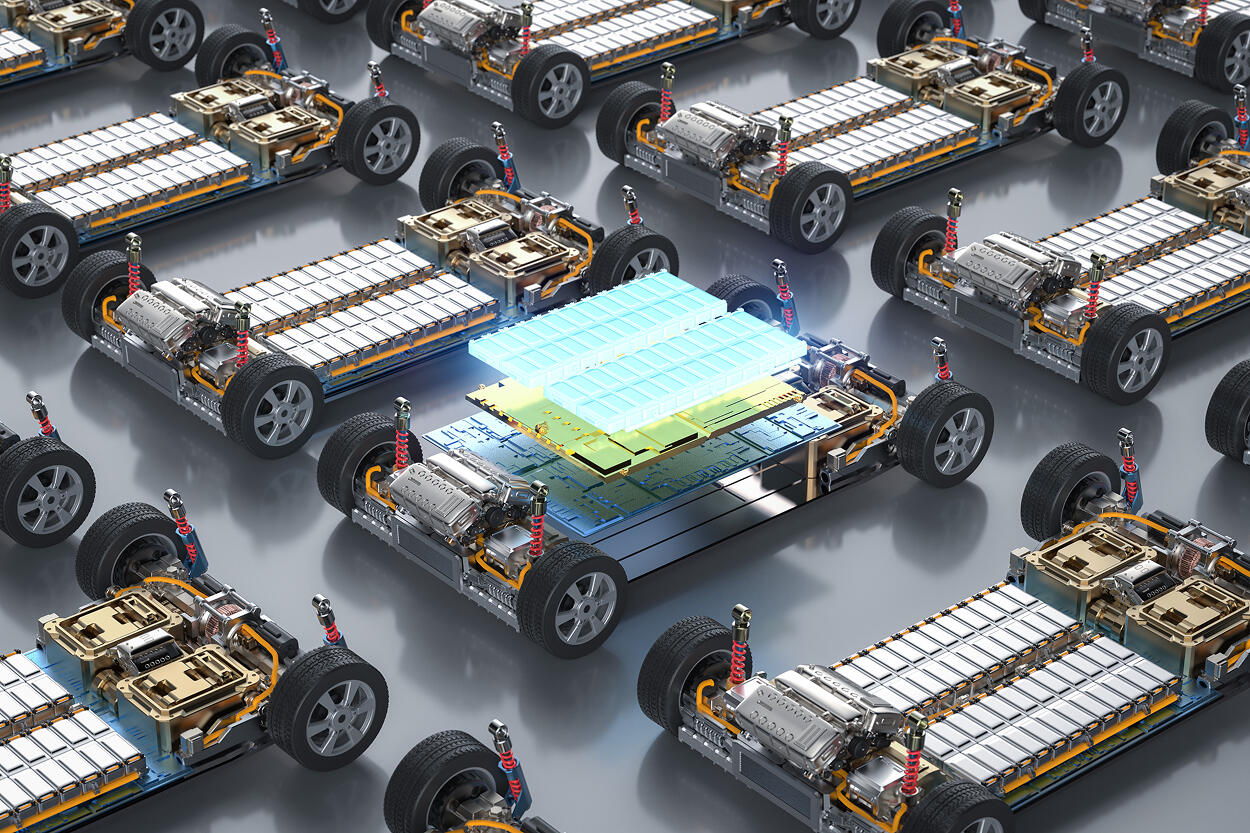

2. Electric Vehicles (EVs)

Electric vehicles are a major driver for SBC innovation. Traditional EVs dedicate up to 30% of their weight to the battery pack.

SBCs could change this by allowing:

-

Car panels, roofs, and frames to store power directly.

-

Weight reduction for greater range and efficiency.

-

Enhanced safety, since the distributed structure reduces the risk of thermal runaway in one concentrated battery module.

Volvo Cars has already experimented with prototype panels made of carbon-fiber composites that store energy. In testing, they achieved significant weight savings while maintaining vehicle rigidity.

3. Aerospace and Drones

In aviation, every gram counts. Structural battery composites could:

-

Reduce aircraft weight dramatically, improving fuel economy or electric range.

-

Enable drones to fly longer and carry heavier payloads by making their wings energy-storing structures.

-

Lead to self-powered aircraft fuselages in the future.

NASA and Airbus have shown interest in these materials for electric flight prototypes — where every surface contributes to energy storage.

4. Wearable Technology

SBCs and smart materials can be integrated into clothing, watches, and medical devices, creating self-powered systems without bulky batteries.

For example:

-

Smartwatches that draw power from their carbon-fiber casing.

-

Exosuits or health monitors that charge through structural materials embedded in fabrics.

Smart Materials: Beyond Structural Batteries

While SBCs are at the forefront, they belong to a broader movement toward smart materials — substances that sense, respond, and adapt to environmental changes.

Types of Smart Materials

-

Piezoelectric materials — generate electricity from mechanical stress.

-

Shape-memory alloys — return to their original shape when heated.

-

Electrochromic glass — changes transparency based on voltage.

-

Self-healing polymers — repair microscopic cracks automatically.

By combining smart materials with SBC technology, engineers could design devices that are self-powered, adaptive, and durable — capable of surviving extreme conditions with minimal maintenance.

The Benefits of Structural Battery Composites

1. Weight and Space Savings

Eliminating separate battery packs significantly reduces mass and frees up design space — vital for EVs, drones, and aerospace.

2. Improved Efficiency

Energy is stored where it’s used, reducing transmission losses and improving power delivery efficiency.

3. Safety and Stability

Solid-state SBCs are less prone to overheating or leaking, making them safer than liquid-electrolyte batteries.

4. Design Freedom

Manufacturers can create sleeker, thinner, and more aerodynamic devices without compromising performance.

5. Sustainability

Fewer materials, fewer manufacturing steps, and lower overall energy use mean SBCs could help reduce the environmental footprint of hardware production.

Challenges to Overcome

Despite its potential, SBC technology is still in early development. Key challenges include:

-

Lower Energy Density: Current SBCs store less energy per kilogram than advanced lithium-ion batteries.

-

Complex Manufacturing: Integrating battery chemistry and structural design requires new fabrication techniques.

-

Durability and Lifecycle: Repeated stress could degrade electrochemical performance.

-

Recycling and Repair: End-of-life disassembly for multi-function composites remains difficult.

However, ongoing research at institutions like Chalmers University, MIT, and Oak Ridge National Laboratory aims to solve these limitations through nano-engineering, solid electrolytes, and recyclable composites.

The Role of Materials Science in Performance Engineering

Historically, computing and hardware innovation have revolved around silicon chips and electronic circuits. But with the rise of SBCs and smart materials, materials science itself is becoming a performance driver.

This shift means the future of hardware design won’t just rely on faster processors or denser memory — it will depend on smarter, multifunctional materials that can store energy, manage heat, and even self-repair.

Hardware Beyond Silicon

-

Graphene composites could deliver ultra-fast charging and flexible electronics.

-

Piezoelectric nanogenerators could convert vibration into usable energy.

-

Metamaterials could manipulate light and sound for next-gen sensors.

SBCs are the first step toward a new class of energy-integrated, intelligent hardware systems.

Future Outlook: From Prototypes to Real Products

Over the next decade, we’ll likely see SBCs evolve from research labs to mainstream products.

Short Term (2025–2028):

-

Integration in small devices (drones, laptops, wearables).

-

Demonstration vehicles using partial structural batteries.

Medium Term (2028–2035):

-

Commercial EVs and aircraft with full SBC panels.

-

Smart materials enabling energy-adaptive architecture and robotics.

Long Term (Beyond 2035):

-

Self-charging devices and vehicles.

-

Buildings and infrastructure that store and release energy.

-

A complete merge of materials, energy, and intelligence.

As energy storage, AI, and advanced manufacturing converge, SBCs may define the next revolution in sustainable technology.

Conclusion: The Structure Is the Power

Structural Battery Composites represent a profound shift in how we think about hardware, power, and performance.

By turning structures themselves into batteries, engineers can create devices that are lighter, stronger, and smarter — bridging the gap between energy and design.

From laptops that power themselves to electric cars where every panel stores charge, SBCs blur the boundary between form and function.

As the World Economic Forum notes, the integration of materials science and energy storage could redefine the very foundation of modern technology — transforming how we power the devices and vehicles of tomorrow.

The future won’t just be powered by batteries.

It will be the battery.